Attacked for failing to discover a light filament after 1000 tries Thomas Edison famously replied; “But now I know 1000 materials that don’t work.” I’m in a similar boat. I have tried two known oar theories, and have now come up with a third which works, but may not be the complete answer.

The simplest theory according to William of Ockham of Ockham’s razor fame is most likely the correct one. In this case it happens to be; “To every action there is an equal and opposite reaction.” (Newton’s third law). That is, as the oar blade pushes on the water the water pushes back. This theory has been elaborated in a scientific paper that excited me some years ago; ‘The force from the blade on the water is generally normal (at right angles) to the blade surface at all times. The only exceptions to this are at the catch and the release. This force can be broken down into the following two components: 1) parallel to the direction of the boat, and 2) lateral to the direction of the boat. The lateral force does not contribute to the forward motion of the boat. Between 70 and 110 degrees, the oar’s angle with the boat’s direction provides the greatest forward force on the boat. Ideally the rower’s force should be highest when the oar is in this position.” (Virginia Technical Institute, Mechanical Engineering, Tidwell 1998)

Well: “The lateral force does not contribute to the forward motion of the boat.” It seemed logical, so I made an oar that is always at right angles to the boat to eliminate the lateral (sideways) force.

The articulated oar blade (Take in photo A)

What a disappointment! It was very easy to pull at the catch and release and not very efficient mid stroke. However it was a bit like going nowhere and moved the boat less than a conventional oar. I dumped the project, but gradually figured out why it didn’t work. Of course, at the catch the blade was going two-thirds sideways, and only one-third aft. Although it was easy to pull, two-thirds of my action was being wasted. How then was the conventional oar so much more effective at other than right angles, when most of its energy was being wasted because “the lateral force does not contribute to the forward motion of the boat?” I have come to the following conclusions about this, especially for low load conditions.

- For a well designed curved blade on a boat in motion, the water will flow over the blade at the catch, as the boat moves forward, in the same way as the wind blows over a sail and drives a boat to windward. As a matter of interest the area of a normal oar blade is equivalent to a wind-sail of 70 m2 or 760 square feet when the difference in density between air and water, is taken into account.

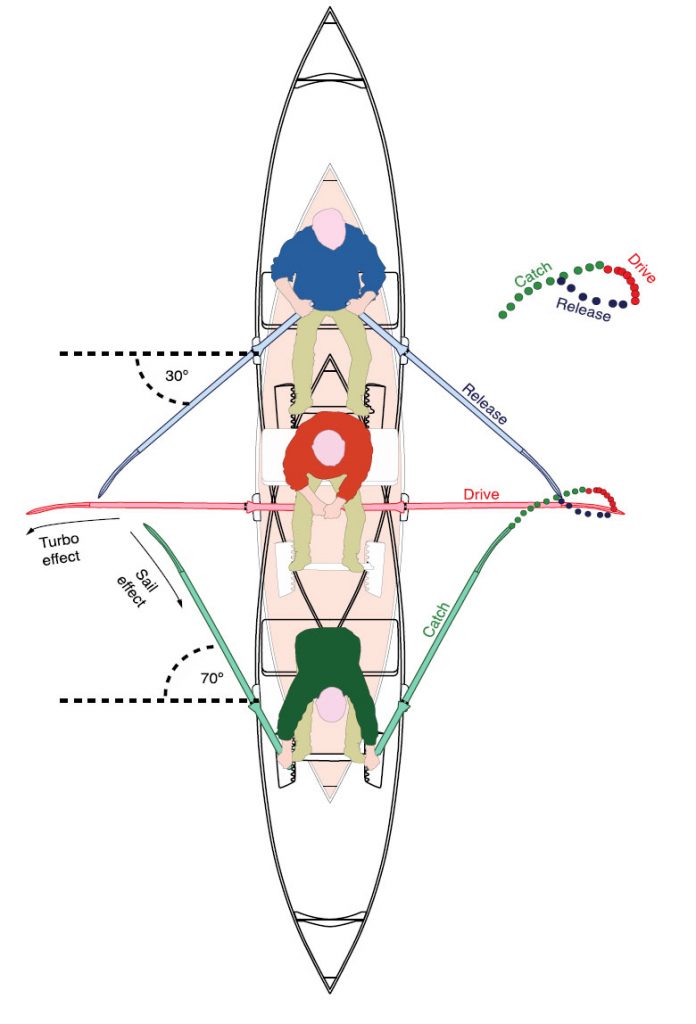

This does not apply to a boat getting under way as the blade will stall. This explains why starting strokes are short and close to right angles with the boat. Further readings on “Hydrodynamic lift” in relation to rowing confirm my conclusion. They disclose the counterintuitive fact that the oar moves forward in the water by around 4 inches (10 cm.) during the rowing stroke. The following diagram based on actual photos taken during a rowing stroke, illustrates this.

The above diagram shows the rower at the three stages of the same stroke (the catch is the start, the drive is the middle, the release is the final part). The dots represent the position of the blade in the water about every 5 degrees of stroke. Notice especially that that the blade has sailed forward in the water. This “sailing” occurs for 60 degrees of catch and release while stalling or moving back in the water occurs for 40 degrees of drive. It must be borne in mind that even a flat blade will appear to sail forward at the catch because of the forward motion of the boat. The aim is to make a blade that will sail better. (Data from “Hydrodynamic Lift in the rowing strike.” Ken Young, University of Washington, 5 June 1997)

- The lateral motion of the oar will now induce the water to flow over the blade rearward creating a forward thrust in return.

- Greater efficiency is offered at the catch, as the oar is moving sideways into clean water. The parallel to this is the greater efficiency of a sailing boat on a reach (catch) than a run (drive).

- When the oar is at right angles to the boat it loses energy through slippage. This slippage amounts to about 30% at the tip, which travels furthest. This argues for a shorter wider blade, but for reasons of balance, and clearance on the return stroke, this is not practical beyond a certain point.

Years ago I was interested to observe the native use of canoes on the remote island Tagula in New Guinea, where I had been shipwrecked. Although they had efficient paddles they would always use a pole to propel the canoes when the water was shallow enough.

The pole had no slippage of cvourse, and gave close to 100% efficiency (in contrast to estimated efficiencies of 70%-80% for racing oars and probably less for their paddles). They would allow their weight to fall backwards off the canoe while poling and push themselves upright, at the last, in the most skillful manner.

Excited about the interesting and counterintuitive theory of the sailing oar, I made a prototype oar that is shaped more like a sail to improve its performance. The leading edge is curved aft at 45 degrees to the line of the shaft and the blade is curved length ways and sideways to encourage non turbulent flow.

Testing with a hose showed the water attaching much better to the rear of the prototype.

Now for the acid test, how would it work? Had I wasted my time again? I chose a calm day to test the oar down on the Hawkesbury River and opposed the prototype “sailing oar” against a more conventional blade of the same area, in which the blade curves evenly through 15 degrees. The test had to be done under calm conditions. If the boat was carefully rowed with equal force on each oar, prototype one side, it should turn away from the prototype if more efficient, and towards it if less efficient. After twenty careful test runs, eyes closed, eyes open, the dory consistently turned away from the prototype. It was even more effective when a long catch was used. The feel at the catch is of a quite refined performance, with a pull propelling the boat further than expected.

Sometimes the laws of physics work against you. In this case not so, the prototype is very much stiffer because of its more compound shape. This enables a lighter blade that has the important effect of reducing outboard weight where such a reduction will have most effect.

Where to from here? Well of course even more radical shapes are to be tested until the shape becomes too extreme.

End of part 1

Table of Contents

Oar Theory Part 2.

Thanks to Francis Herreshoff and John Gardiner, the Herreshoff rowing boat we build is as close to perfection as it can get. However the rowlocks available were most unsatisfactory so I set about inventing, designing and manufacturing the Gaco rowlock. Still, there were the oars. If they were not heavy and clumsy they had poorly shaped blades. Enquiries at a racing oar manufacturer indicated a cost of over five hundred and fifty dollars and no guarantee that a satisfactory rowlock would suit them. So I have spent about a decade on and off investigating how oars work in the water and the best way to build them. A novel and simple way of shaping a stiffer and lighter shaft is described separately (the isosceles trapezoid shaft). In the following article I will describe a third theory of how an oar works. Part one described two theories and my investigations of them. Part two describes my investigation into a third and novel theory proposed by a chemical engineer. Part two also describes my final preferred design and its performance under racing conditions. A proper understanding of how oars work should inform oar selection and improve the rowing stroke.

The Turbo Oar

After engaging in an informal consultation with a friend of mine, I have felt obliged to test a new oar theory. Col Putt is a chartered chemical engineer who now teaches at Sydney University. He has been fitted with so many titanium joints that he insists upon expiry that his body be taken to the scrap merchant. Upon visiting him in hospital where he was being fitted with another metal joint I gave him a draft of my article on the sailing oar. A few days later he called back with an oar theory he was excited about, related to the mechanism of a centrifugal pump. A centrifugal pump has an inlet at its central hub and rotating vanes propel the water in a circular motion where the centrifugal force sends it through an outlet at the circumference. According to this theory “The oar acts to project a jet of water away from the centre of rotation, in this case the oarlock. The curved end of the blade impels the water in a more effective direction for propulsion through most of the stroke.” This analysis bears thinking about especially when designing the blade.

In discussion with Col, I suggested that I should increase the angle, between blade tip and shaft, to 55%. “No” said Col “try 60%.” So I set to work and through some unexplained error ended up with an even more extreme angle change of 65%. The image below shows the blade shape and illustrates the anticipated, centrifugally driven, flow of the water during the stroke.

Tests were carried out on the three different types of blade, the reaction blade (A15) the sailing blade (A45) and the turbo blade (A65). The comparison tests were carefully carried out in waters unaffected by currents or wind. The oars were opposed to each other in tests repeated till results were consistent. Summary of results:

Full stroke: The turbo blade was superior to both blades. In order to determine why and where it was superior, tests were then carried out comparing the blades at the catch, drive and release.

Catch:

The sailing and turbo blades were superior to the reaction blade. The sailing and turbo blades were equal to each other.

Drive and Release:

All types of blade were equal at the drive and release.

Conclusion: The order of blade performance was as follows;

- Turbo blade.

- Sailing blade

- Reaction blade.

It is interesting that the sailing blade is equal to the turbo blade when the different phases of the stroke are tested separately. However the turbo blade is very definitely superior for the full stroke. This result seems to support the centrifugal effect of the water where, “the oar acts to project a jet of water away from the centre of rotation.” It is probable that breaking up and testing the stroke at its component parts prevents the turbo blade establishing a consistent flow of water along the blade. The action of redirecting the water aft, results in a forward reaction on the blade that increases its efficiency.

It helps to reconsider what is happening in the stroke. It must be remembered that the oar blade is changing the direction in which it pushes the water by about 90% during the stroke. That is, it pushes the water in one direction and then changes its direction, but the water it has been pushing continues in the previous direction and thus slips off the end of the oar. We are really talking about Newton’s first law (“A body continues in its direction and speed of motion unless acted on by an external force.”) rather than centrifugal force.

The enhanced sailing blade. One last test.

It is well known that wings and sails get their most lift from the low pressure side. To enhance this lift every effort is made to prevent eddies forming as the fluid flows around the wing or sail. Since my “sailing” blade had a sharp leading edge, eddies could detract from the smooth flow over the blade. Consequently I made a blade with a nicely rounded and faired leading edge, fully expecting it to have an improved performance.

Repeated tests indicated that the enhanced oar was slightly inferior to the unfaired sailing oar. It appeared that the turbo effect was more effective than the sailing effect. The unfaired blade allowed a cleaner exit of the water off the end of oar, while the faired blade caused eddies to form at the tip thereby obstructing the clean flow of water. Exit of the water off the blade is more important than entry onto it.

The Acid test.

Easter Sunday each year, all and sundry have a rowing race around Dangar Island on the Hawkesbury River in boats considered suitable for safe, island commuting. They must be able to carry three people in reasonable comfort and safety. The motto for the Dangar Dory Darby Day is “No smelly engines, just smelly people”. The most numerous rowboat is the Herreshoff rowboat. Now here was the place to test out the new oars.

I have to confess at this stage that I was trying to use a combination of tactics, technique and technology to compensate for my aging body in this race. A second turbo oar was made to pair the existing one and the pair was tried on the river. They seemed to exert such a grip on the water that my arms felt like they were pulling out of their sockets. Some would argue at this point for bendy oars but I preferred to change the mechanical advantage. Stops were put in place to increase the inboard to outboard ratio from 26% to 30%. Now the handles overlapped on the rowing stroke so the bottom spacer of one Gaco oarlock was trimmed off to lower one oar and facilitate overlapping. With some practice the overlap proved easy and enabled a longer efficient stoke that was quite comfortable and very satisfying.

Incidentally the oar acts as a first order lever even though science teachers will correctly say that the load is at the gunwale and the fulcrum (pivot) at the blade water interface making it a second class lever. This would be so if the rower were to be standing outside the boat and pushing whilst himself stationary. For instance imagine the oar completely outboard with the handle at the oarlock. For a rower, the boat would not move but a person standing in the sand and pushing on the handle there would be no problem. However for calculation purposes the oarlock is the fulcrum and the blade water interface the load. Thus if the oar is say 25% inboard then the blade (which is three times as far outboard) will travel three times as far as the oar handle. Thus the rower will move the boat about three times as far but with about one-third the force. Although we consider rowing boats slow, a well designed craft will travel at about twice walking speed. We have to view the function of the oar as moving the water past the boat rather than the boat through the water. If the turbo blade has less slippage, the rower may improve the force by moving the handle further inboard without losing any motion. In other words what is lost by having to move the handle further is more than gained by the greater efficiency of the oar blade. In practise it enabled me to conserve energy for the seventeen minute race, by achieving the same performance with less effort.

Technique: the resistance of a displacement craft through the water is proportional to the square of the speed. To go twice as fast requires four times the power, so it is best to keep the speed as constant as possible. This means as quick a recovery as possible and a good effort at the catch. At the catch the boat has slowed because the oars have not been driving for a period, and the rower’s body has suddenly stopped moving aft, thereby acting as a brake. There is a temptation at the drive to pull harder and this can result in acceleration into a high resistance zone, with the stern squatting and the bow rising, with not much increase in speed. This energy is best expended at the catch and to a lesser extent at the release. As a general rule it is best to use the same force through the whole stroke. As well, and this is an argument for overlapping oars, a long stroke is more efficient because energy is wasted changing the direction of movement of the body and oars at the ends of the stroke. That is, the fewer strokes the less energy is wasted. Small amounts of energy may also be conserved by relaxing the arms and body during the recovery stroke and by gripping the oars correctly. When D-shaped shafts are used, the effort required to hold the blade vertical in the water is obviated. Now the handle can be gripped simply by hooking the fingers around the handle.

Over the years we have had some rowers who train enthusiastically for this race, and there is somewhat of an atmosphere conveyed by some lines from an Australian bush poem

“There was movement at the station, for the word has passed around That the Colt from old Regret had got away

And had joined the wild bush horses – he was worth a thousand pounds So all the cracks had gathered for the fray.”

No quarter is given in the race and starters age from eight to eighty. The only stipulation is that the island must be circumnavigated. Tides can encourage tactics like rowing under wharves and across reefs. One year several boats found themselves stranded on oyster strewn reefs. As they tore the bottom out of their boats and their feet I thought I could hear mutterings of “Oh well! It’s all part of the rich tapestry of life.”

The race record around the 1.46 nm island is held by Rodney Bryson who smoked around the island at an average speed of 5.56 knots which is the theoretical top speed of the 15’9’’ waterline craft (top speed in knots for displacement craft = 1.4 times the square root of waterline length in feet)

The starters range from eight to eighty. Rodney, the race record holder, lines up with a future champ for the start.

As usual I missed the inside running by involving myself in the running of the races, organising boats etc. As I carefully manoeuvred under the first wharf for a short cut, Admiral Nelson came charging through and rammed me into the piles losing me some time, thanks Admiral! Then came the long slog across the south side of the island overtaking some of the sluggards. Then around the west side of the island where I gradually overtook Rodney and Jonathan who have both been keen competitors and former winners. Was it the oars? Or was it fitness? Then down the north side of the island to come fourth.

What a fantastic result, three young fellas were ahead of me. First came Asher Ashford (aged 18) in a race record speed of 5.57 knots. He was followed by David Tilley (aged 29, 5.49knots) Peter Miller (aged 42, 5.39knots) and myself John Murray (aged 70, 5.26 knots). Rodney Bryson came fifth (aged 46, 5.19 knots) and down the pack a future champ Luka Dahl (aged 8, 3.11 knots).

The sniffer dog does the rounds, checking for illegal drug use.

After the race Rodney rowed my boat to test a front view mirror I had fitted to my boat. He came back so impressed with the oars that he determined to make a new pair for himself.

Rodney related that when he was front runner and record holder in the past, that he used to carry the dory on his car all the time, and any chance for a training run took it. It is worth noting that Rodney made his record using oars that looked somewhat like clubs, fitness trumps all. Of course all other things being equal a decent set of oars will trump a poor set.

Colin has reviewed this paper and comments that he once watched some fellas rowing at Halfslo in Norway around 1973. As he observed these fellows confidently rowing away from the upside of a 200 foot waterfall, he was surprised to observe that they were using long saplings as oars. The ends were quite whippy and had no blades at all. So there you go! There really is more than one way to skin a cat. Colin introduced himself to these Vikings whose names were William and Harold Hardarse. He concluded they were aptly named as the seats comprised two branches whose natural shape fitted the sides of the boats such as knees might and must have been hard on the butt. I have learned that the Vikings employed oars and seats described above, though they would flatten the rear side of the sapling where it entered the water.

There are many factors affecting performance but youth and fitness must be the most important. It is pleasing to see that size and strength do not seem to favour larger people. The lighter weight of the smaller person lowers the resistance of the boat in the water. Even more pleasing for us, is to see the young people getting involved and showing us older folks a clean pair of heels. There is a wonderful sense of community and sportsmanship involved with the day and no apparent generation gap. Asher is keen to get his own boat so he, his dad and I, will be building two boats where he will not only acquire a boat but the boatbuilding skills needed to make one.

As far as the oars are concerned it seems all three theories apply to their efficiency in the following order: Action and reaction> Centrifugal effect > Sailing effect. Various readings imply that the efficiency of the racing oar is between 70% and 80%. I expect that the turbo oar has a considerable efficiency increase over some of the commercially available oars, and may well be an improvement on the racing oar.

As far as the rowing race is concerned, the young fellas have shown their mettle so I will have to “…take kindly the counsel of the years and gracefully surrender the things of youth.” (Desiderata)

POSTSCRIP: One year on (2012) and Asher and his sister have teamed with me to build Swift dories (Herreshoff rowboats) for themselves.

For some months Asher trialled the Sailing oars against the Turbo oats. He came down decisively in favour of the Turbo oars and bought a pair from me. He subsequently won the race convincingly and broke the race record by 15 seconds, in a year that the race was slow (30 seconds slower for me) because of the tides.

His time was equivalent to a speed of 5.65 knots which is a remarkable achievement, no doubt attributable also to his youth, fitness and determination.

John Murray comes from down under and has invented and manufactures the Gaco oarlock. He has been rowing for longer than he cares to admit. He has built his own trimaran and sailed it around the world. He spent a year of his time sailing up and down the US east coast where he enjoyed the kindness, courtesy, and eccentricities of the American people. He has worked as an Industrial Chemist, science teacher, boat charterer and in the copper mines at Bougainville.